"sony1492" (sony1492)

"sony1492" (sony1492)

06/16/2019 at 13:00 ē Filed to: SC400

4

4

3

3

"sony1492" (sony1492)

"sony1492" (sony1492)

06/16/2019 at 13:00 ē Filed to: SC400 |  4 4

|  3 3 |

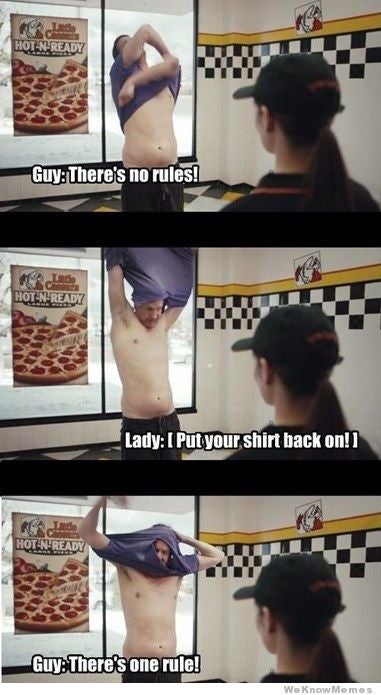

It wasnt catastrophic failure more of a fizzle, First letís run through the photos.

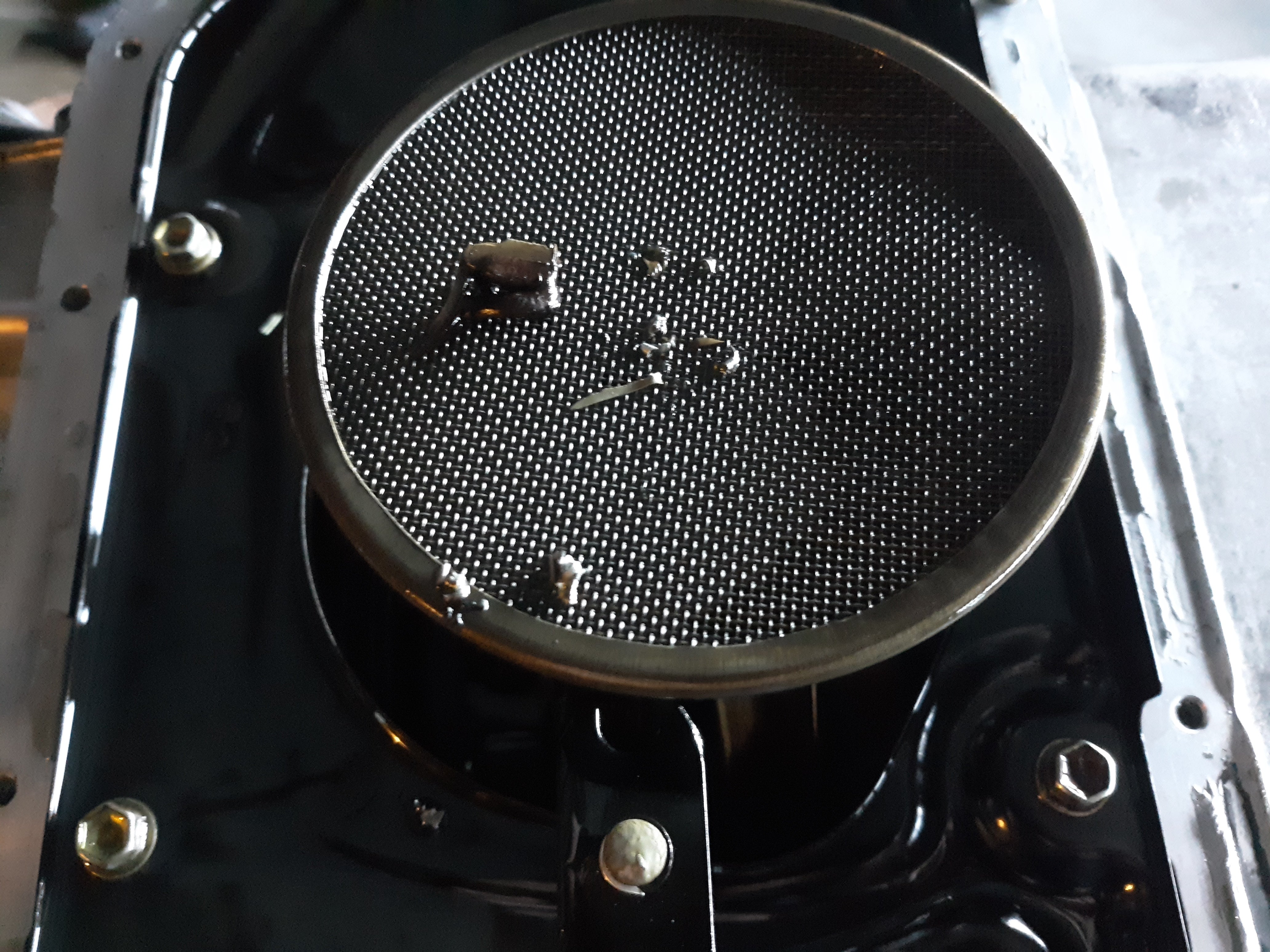

Oil pump pickup with bits of metal

!!!CAPTION ERROR: MAY BE MULTI-LINE OR CONTAIN LINK!!!

!!!CAPTION ERROR: MAY BE MULTI-LINE OR CONTAIN LINK!!!

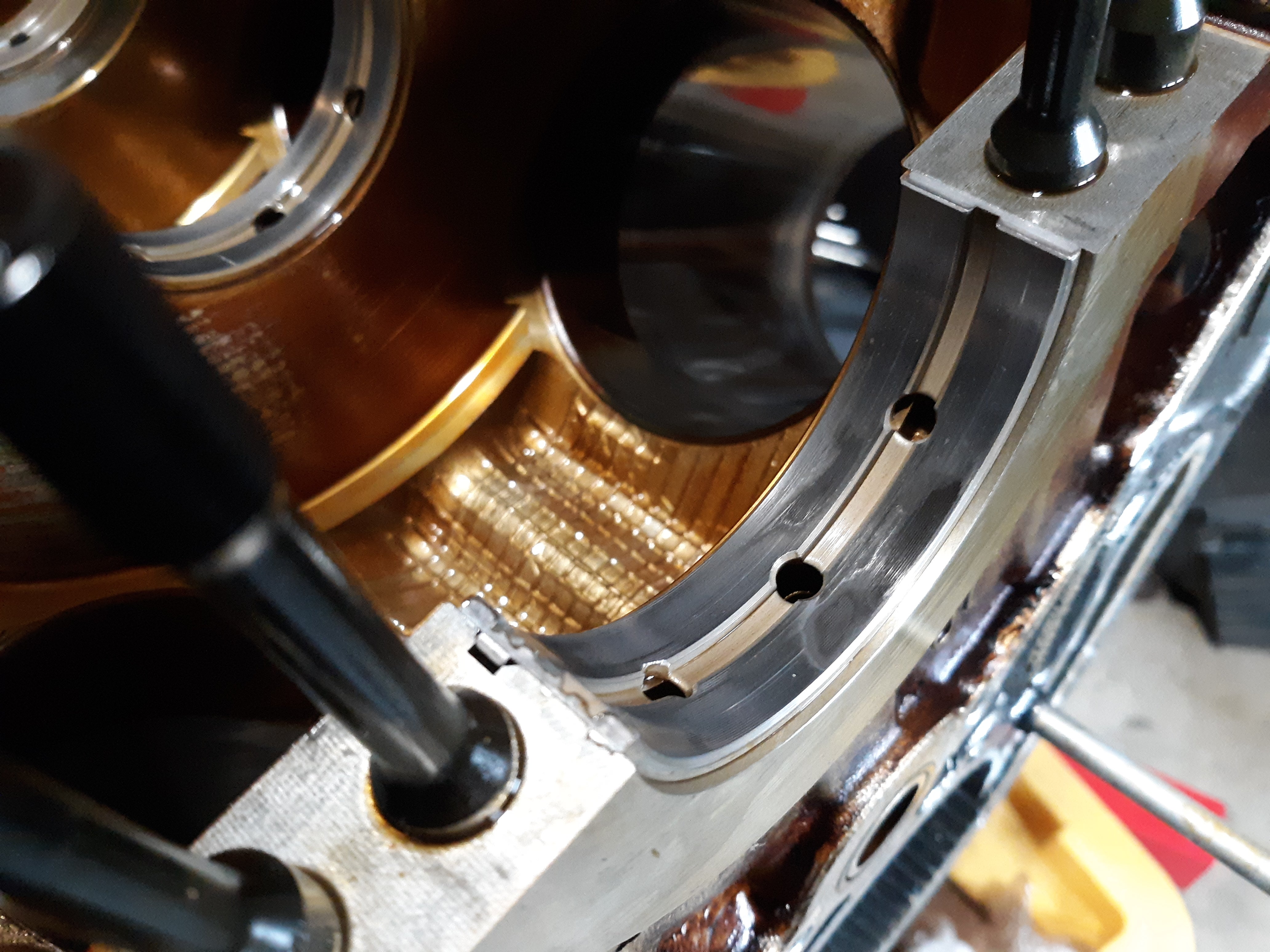

Theres a fragment still embedded in the bearing

The Turbo oil Return fitting location wasnt decided until the exhaust was finished and the engine was in the car. It occurred to me the only return location was the sump just under the crank pulley, so I drilled and tapped the the fittings in car. This left shards of aluminum floating around in the oilpan and laying in the crankcase, draining the oil afterwards evidently didnt remove many of the bits of aluminum.

The shards got sucked into the oil pump getting flung under the pistons to get caught in between the cylinder wall and piston marring the surfaces.(which caused the blowby that was leading to turbo drain issues). It also got caught in the main bearing surfaces leading to the wear shown above.

Next step will be a rebuild using stock components save for Cosmetic head gaskets(potentially a lower compression ratio closer to 9:1 instead of 10:1) also plan to balance the pistons/ rods since Iím in there.

Bylan - Hoarder of LS400's

> sony1492

Bylan - Hoarder of LS400's

> sony1492

06/16/2019 at 13:06 |

|

Ouch! Sounds like you've got it well under control though, and these engines are pretty easy to work on, especially out of the car. Can't wait to see some rebuild pics! Very jealous of your projects

I like cars: Jim Spanfeller is one ugly motherfucker

> sony1492

I like cars: Jim Spanfeller is one ugly motherfucker

> sony1492

06/16/2019 at 16:22 |

|

Oh, all of those bits should be INSIDE the engine, not outside. That could be a part of it, too.

sony1492

> I like cars: Jim Spanfeller is one ugly motherfucker

sony1492

> I like cars: Jim Spanfeller is one ugly motherfucker

06/17/2019 at 01:18 |

|